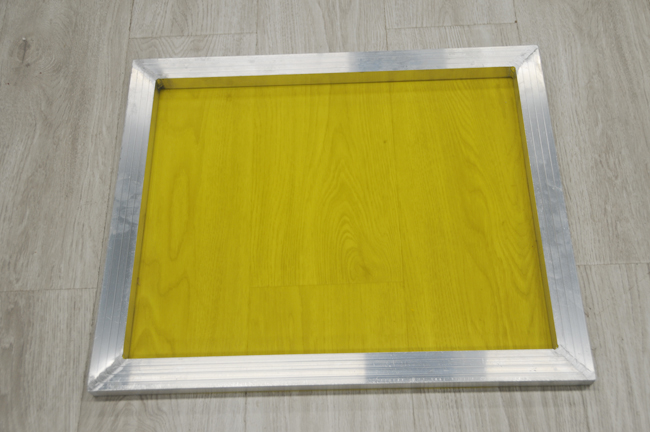

Therefore you need a lower mesh count with large holes in order for all the particles to pass through properly. These inks have particles in them that will not pass through the typical mesh sizes. Lower mesh counts like 40-86 are used for shimmer and glitter inks. Also if you are printing with a little thinner viscosity colors of inks, you may want to use the 156 mesh so not too much ink is passed through your screen. 156 mesh also lays down a little thicker layer of screen printing ink but offers you some higher detail ability in your image due to the finer mesh. Its also a recommended mesh for white flash plates because many times you will only have to make one print impression which speeds up production time. Its great for block text letters and larger spot color designs. 110 mesh lays a fairly thick layer of ink down. Your basic and most standard mesh sizes are 110 and 156. However we can give you a general outline of what sizes to use for certain types of printing. Since there are many variables involved in silk screen printing we cant tell you exactly what mesh sizes are used for what applications. 86, the difference is so negligible and small that it will not matter in your final results. If the mesh count is fairly close, such as the difference between 155 vs. You will notice that different companies have different sizes available. On the other hand, if you are trying to print a thicker ink (such as white) through to high of a mesh screen, barely any ink will print through the mesh. Also if you are using a thinner ink, the ink will also flood through the larger holes and soak onto your shirt or substrate making your image blurry as the ink bleeds. The fine lines or dots in the image will simply fall through the holes in the mesh not giving you a correct representation of what your image should be. If you have an image with extremely high detail, a lower mesh screen wont hold the high detail. The size of the mesh has a lot to do with how detailed your image is and how thick the ink you are using is. The higher the mesh count, the finer the threads and holes are in the screen. For instance, a 110 mesh screen has 110 threads crossing per square inch. Mesh size is measured by how many threads of mesh there are crossing per square inch. More about screen printing mesh size:ĭifferent mesh sizes are used for different applications in the screen printing process. If you're looking to maximize performance in your shop, aluminum frames are a great item to add to your screen printing equipment. Aluminum frames are also light weight which makes shipping less expensive and saves you money in the long run. Once cleaned, the frames can then be re-stretched which will give you the ability to use that frame for years of hard work in your shop.

Aluminum silkscreen frames professional#

The mesh and glue are simply removed from the frame using a professional tool that doesn't damage the aluminum. Aluminum frames can also be stretched and re-stretched many times.

This will insure a flat frame through thousands of prints to come.

Unlike wood silk screen printing frames, when exposing frames to water in a dip tank or washout sink aluminum frames will not warp. The advantage of an aluminum screen printing frame is the durability and longevity it retains. Screens are stretched pneumatically to industry standard tensions using high grade monofilament poly mesh and held using cyanoacrylate glue. Once welded, the frames are then sandblasted to insure mesh bonds properly to the aluminum and retain its tension through thousands of imprints. All aluminum frames are extruded with the highest grade aluminum and cut and welded right here in the USA. Ryonet provides high quality aluminum pre-stretched screens in various sizes and mesh counts.

0 kommentar(er)

0 kommentar(er)